➔ Index of ⦁ Introduction to Electromagnetic Compatibility ⦁

Introduction to EMC: an overview

What is EMC, why is it so important in electronic design and why you should consider it since the earliest stages of your project

Introduction

Electromagnetic Compatibility (EMC) is the field that ensures electronic devices and systems can function properly in their environment without creating or suffering from unwanted disturbances. It is built on two complementary aspects: Electromagnetic Interference (EMI) and Electromagnetic Susceptibility (EMS). EMI refers to the unwanted electromagnetic energy a device emits, which may disturb the operation of nearby equipment. EMS, on the other hand, describes a device’s ability to withstand external electromagnetic disturbances without malfunctioning. In other words, EMI is about how much interference a device produces, while EMS is about how well it resists interference coming from outside sources. By controlling both, EMC guarantees that products not only comply with international regulations but also deliver safe, reliable, and efficient performance in sectors ranging from consumer electronics to aerospace and medical technology.

A common example of electromagnetic interference occurs when a poorly shielded switching power supply in a cheap electronic device disrupts nearby equipment. Imagine a desktop computer placed next to a radio receiver: if the computer’s power supply emits excessive high-frequency noise due to inadequate filtering, these emissions can radiate through the air or travel along the power lines. As a result, the radio may pick up this interference as static or buzzing sounds, reducing the clarity of the broadcast or even making certain frequencies unusable. In this scenario, the computer is the source of EMI, while the radio demonstrates limited EMS (susceptibility), since it cannot effectively reject the unwanted signals. This simple case illustrates why EMC is critical—devices must limit the noise they generate and at the same time be robust enough to resist disturbances from their environment.

Instruments and tool

EMC testing - Keysight

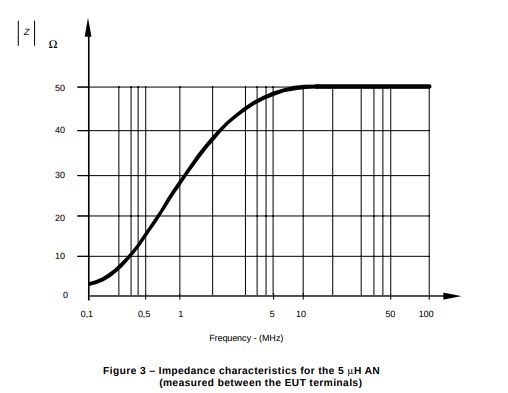

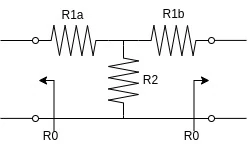

In EMC testing, a wide range of specialized instruments is used to measure and evaluate both emissions (EMI) and immunity (EMS). Spectrum analyzers and EMI receivers are essential for detecting and quantifying unwanted electromagnetic emissions across defined frequency ranges, while antennas (such as biconical, log-periodic, and horn antennas) are employed to capture radiated signals. For conducted emissions, Line Impedance Stabilization Networks (LISNs) provide a stable and repeatable measurement setup by isolating the device under test from external noise sources. On the immunity side, signal generators, RF power amplifiers, and clamp devices are commonly used to inject disturbances into equipment to verify its resilience. Anechoic chambers and reverberation chambers create controlled test environments free from external interference and reflections, ensuring accurate and repeatable measurements. Additionally, current probes, oscilloscopes, and field probes are used for monitoring, troubleshooting, and validating EMC behavior during both pre-compliance and formal certification testing.

The complexity of EMC

To master EMC troubleshooting and testing, an engineer needs a solid mix of theoretical knowledge, practical skills, and familiarity with industry standards. First, it is essential to understand the fundamentals of electromagnetic fields, waves, and propagation, including the difference between emissions (EMI) and immunity (EMS), as well as the mechanisms of conducted versus radiated interference and near-field versus far-field coupling. A strong grasp of international EMC standards and regulations, such as CISPR, IEC, EN, FCC, and MIL-STD, is also necessary, along with the ability to interpret compliance requirements across industries like automotive, aerospace, medical, and consumer electronics. On the practical side, engineers must be proficient with test equipment, including spectrum analyzers, EMI receivers, oscilloscopes, line impedance stabilization networks (LISNs), current probes, antennas, and field probes, as well as know how to operate in specialized environments like anechoic or reverberation chambers.

Beyond measurement, design knowledge is crucial: engineers should apply best practices in PCB layout, grounding, shielding, filtering, and cable management, while also understanding techniques for power integrity and enclosure shielding. Troubleshooting requires the ability to identify sources of emissions and coupling paths, supported by both time-domain and frequency-domain analysis. Skills in test setup, calibration, and distinguishing real failures from test artifacts are equally important. Simulation and modeling tools, such as SPICE and electromagnetic field solvers (ANSYS, CST), further enhance an engineer’s ability to predict and mitigate EMC issues early in the design phase.

Navigate

Comments

Be polite and respectful in the comments section. In case of doubts, read this before posting.

Posted comments ⮧

Comment section still empty.

INDEX

INFO

STATISTICS

NEXT ARTICLE

CONTACTS

SHARE